Instructions for polishing soft materials using corn cob media.

The following steps will work on soft materials such as Fluorite, Petoskey stones, Turquoise and other soft materials. These instructions are for using dry corn cob as a polish media. This method will work in a Rotary or Vibratory tumbler.

Step 1 – Load the tumbler with the recommended amount of rough Fluorite, add 120-220 grit and run until shaped nicely. This may take 12 or more hours in a vibrating tumbler or up to 30 to 48 hours in a rotary. Check them frequently so that you don’t grind the Fluorite all away.

Step 2 – Wash the tumbler barrel and Fluorite, put the nicely shaped pieces back in the tumbler barrel. Due to the rock that was ground away in Step 1 the barrel will not be full. Add ceramic media to make up the difference for the rock that was ground away and run them in 500 Grit Aluminum Oxide for about 12 hours in a vibrating or 24 hours in a rotary tumbler.

Step 3 – Wash the tumbler barrel, Fluorite and ceramics and run them in 1000 Grit Aluminum Oxide wet for about 12 hours in a vibrating or 24 hours in a rotary tumbler.

Step 4 – Wash the tumbler barrel, Fluorite and ceramics. Remove the ceramics from the Fluorite and save them for the next time you need them in Step 2.

Fill the tumbler barrel approximately 3/4 full of dry corn cob and add about 1 1/2 tablespoons of Aluminum Oxide polish per 1 lb of corn cob.

Note: This is a dry step, DO NOT add water. Divide the Fluorite into 2 or 3 batches (This is to insure that the rock being polished rotates with the corn cob and does not rub against itself). Add 1 batch of Fluorite to the tumbler with the corn cob and polish and run. It may take up to 48+ hours to bring them to a polish in a vibrating tumbler and 3 to 5 days or so in a rotary tumbler. Check them every now and then to see how they are doing.

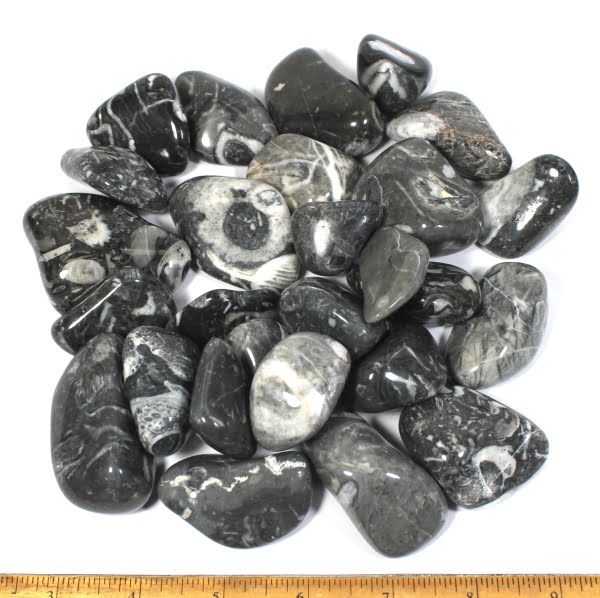

Instructions For How We Polish Fossil Rock & Other Similar Soft Stones using 2mm ball ceramic media

The following steps will work on soft materials such as Fluorite, Petoskey stones, Turquoise and other soft materials. These instructions are for using 2mm ceramic balls as a polish media. This method will only work in rotary tumblers. Vibratory tumblers can use the corn cob method above.

Step 1 – Load the tumbler with the recommended amount of rough Fossil Rock, add 120-220 grit and run until shaped nicely. This may take 12 or more hours in a vibrating tumbler or up to 30 to 48 hours in a rotary. Check them frequently so that you don’t grind the Fossil Rock all away.

Step 2 – Wash the tumbler barrel and Fossil Rock, put the nicely shaped pieces back in the tumbler barrel. Due to the rock that was ground away in Step 1 the barrel will not be full. Add small size ceramic media to make up the difference for the rock that was ground away and run them in 500 Grit Aluminum Oxide for about 24 hours in a rotary tumbler.

Step 3 – Wash the tumbler barrel, Fossil Rock and ceramics and run them in 1000 Grit Aluminum Oxide wet for about 24 hours in a rotary tumbler.

Step 4 – Wash the tumbler barrel, Fossil Rock and ceramics. Remove the ceramics from the Fossil Rock and save them for the next time you need them in Step 2.

Fill the tumbler barrel approximately 3/4 full of 2 mm ceramic ball media and add water to just cover the media and then add about 1 1/2 teaspoons of Aluminum Oxide polish per 1 lb of materials. (ceramic/rock)

Divide the Fossil Rock into 2 or 3 batches (This is to insure that the rock being polished rotates with the ceramic media and does not rub against itself). Add 1 batch of Fossil Rock to the tumbler with the ceramic media and polish and run. It may take up to 24+ hours to bring them to a high polish. Then it’s easy to just reach in and retrieve the polished stones by hand and then add another batch of stones. You do not need to add new polish. Since the 2mm balls are only a polish media, you can store this media in a plastic container and use whenever you need without washing it up.

|

|

|

| Onyx, Serpentine, Petoskey Stone all polished using the process above and 2 mm ceramic media in the polishing step. | ||